18. Victory 2.0 vs Wentworth – Part 1

A deep dive review and comparison of inaugural puzzles from a new company with those made by the oldest and largest laser-cut wooden puzzle maker in the world. (About 8000 words; 24 photos)

This is a detailed review of the Victory Wooden Puzzles Company’s puzzles. Victory is a new British laser-cut jigsaw puzzle company that just launched in September. There are ten 250 piece puzzles in their inaugural offering and this review is based upon my assembly of three of them.

For reasons explained below I felt it necessary also to review a puzzle of comparable size and price from the Wentworth Wooden Puzzles to serve as my standard for comparison. Wentworth was one of the first companies to make laser-cut puzzles, and is believed now to be the largest wood puzzle company in the world. (Data is not available from the company or its competitors to make that a definitive statement, but it is a high probability.)

Because my review and a recounting of my assembly experiences involved four puzzles, and also because I got rather obsessed about finicky details and distracted by other matters (my pre-Christmas music project and the World Cup) this essay became delayed and got to be very long even by my usual standards of verbosity. So I have broken it up into two parts which will be posted separately.

This one is my deep dive review of the puzzles and it is written from the analytical and judgmental parts of my brain (an unfortunate necessity when writing a review.) Part 2 will be probably be posted sometime after Christmas. It mostly comes from the observational and curiosity parts of my brain. It will include walkthroughs of my experiences in assembling the puzzles, which gave me the experience and perspective needed to write this review. It will also include findings from my online research related to the puzzles’ images.

Puzzle images and data

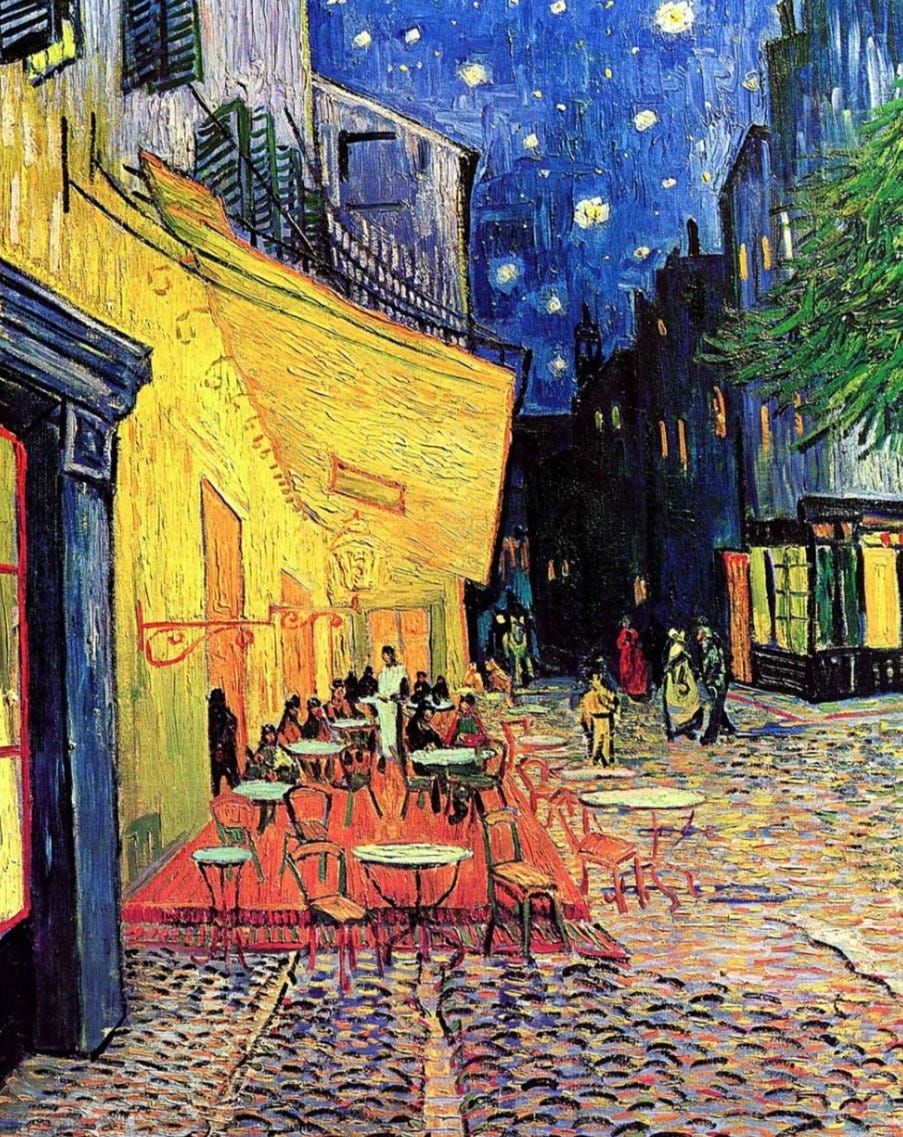

Café Terrace at Night

artist – Vincent Van Gogh (painted Sept 16, 1888)

cutting designer – Aidan Knowles

laser-cut 3 mm medium-density fibreboard

about 250 pieces 36 x 29 cm (14” x 11½”) 4.1cm²/piece

triangular wave background matrix; hidden edges; round knob and V connectors

22 thematic whimsies (9 of which are multi-piece) and a 3D easel w. painting

The Flapper – Life, 1922

artist –F X Leyendecker (Francis Xavier) and the Life cover designer

| cutting designer – Aidan Knowles

laser-cut 3 mm MDF (medium-density fibreboard)

about 250 pieces 36 x 28 cm (14” x 11”) about 4.0cm²/piece

art deco matrix cutting; some hidden edges; knob and V-for-Victory connectors

22 thematic whimsies (8 of which are multi-piece)

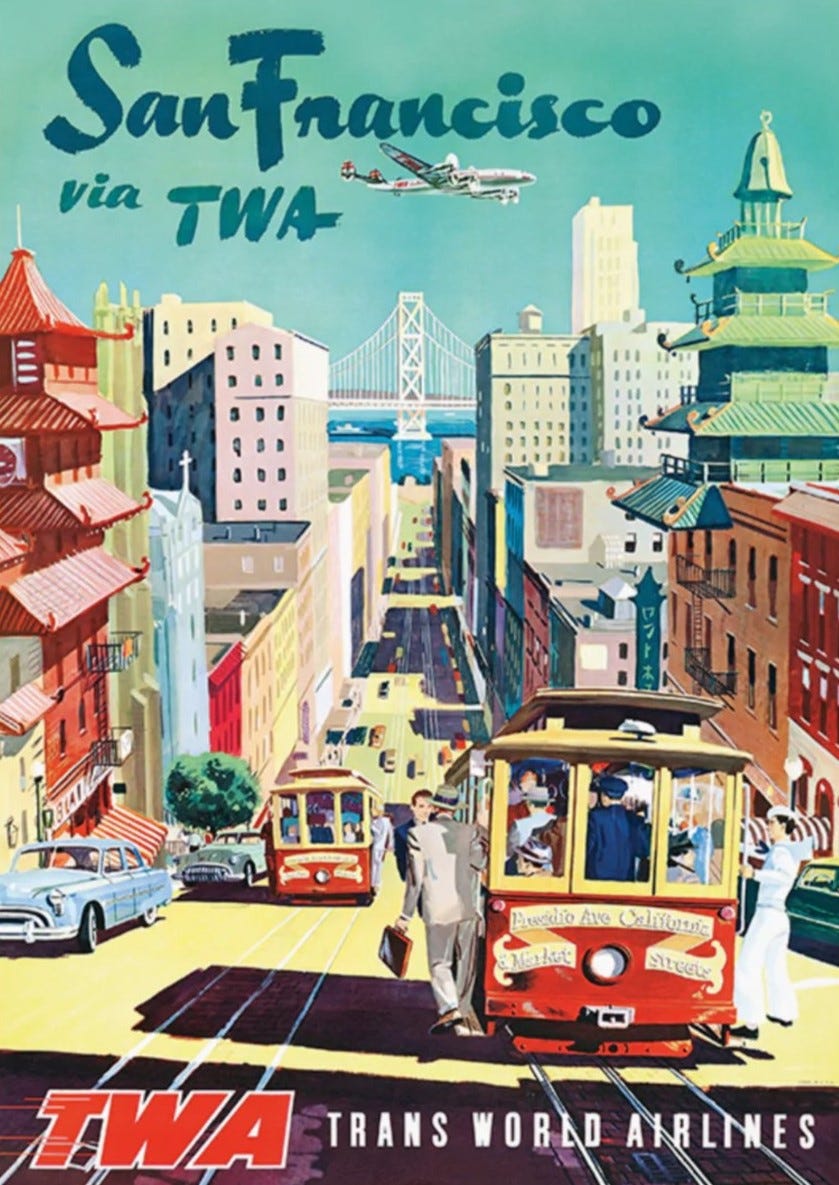

Vintage Poster San Francisco

artist – David Klein; ca1950s

cutting designer – Aidan Knowles

laser-cut 3 mm medium-density fibreboard

about 250 pieces 36 x 25 cm (14” x 10”) 3.6 cm/piece

square geometric matrix cutting; knob, cloud-bank and V connectors

24 thematic whimsies, of which 7 are multi-piece

The Red Vineyard at Arles (for comparison; made by Wentworth)

artist – Vincent Van Gogh (Nov 1888)

unidentified cutting designer

laser-cut 3 mm medium-density fibreboard

about 250 pieces 25 x 36 cm (10” x 14”) about 3.6cm²/piece

standard Wentworth squarish matrix; rounded knob connectors

17 whimsies (all singles); semi-thematic

Review introduction

About a month before the new Victory company launched in September, Andrew Knowles, one of its founders, contacted me. I had posted a message on the wooden jigsaw puzzles Facebook group that I was working on an essay about the history of G.J. Hayter & Company, the makers of the original Victory brand of hand-cut wooden puzzles. Hayter was the largest of the British puzzle-makers back when jigsaw puzzles became an major international craze in the 1930s. (You can read that essay here.)

Andrew told me in confidence that he and his colleagues were preparing to launch this new Victory company which they intended to be something of a revival of the old brand as well as a tribute to it. He wanted to compare notes regarding the history of the former company. I sent him my draft essay and Andrew gave me access to their in-progress website which included his overview of the previous company. After we read each others work he then gave me some new leads and I gave him feedback about his historical summary as well as about other aspects of their draft website.

Andrew appreciated my input and offered to send me a few sample puzzles for free after the company launched so that I could review them. I gladly accepted. I also exchanged correspondence and had phone conversations with him while preparing this review to make sure that I got my facts right. Other than that I have no association with Victory Wooden Puzzles.

As methodology for this multi-puzzle review I decided to refresh my memory about the products of Wentworth Wooden Puzzles. That is the company that absolutely dominates the British wooden jigsaw marketplace and that the new Victory brand is obviously challenging in their selection of format and price range for its own puzzles. In fact, as discussed below Wentworth could be considered to be the current successor to the role that the original Victory brand played in the wood puzzle industry.

I had previously assembled three puzzles that I had bought from Wentworth, but that was quite early on when I had first discovered this hobby. I like to think that both my puzzling skills and my ability to assess them have improved quite a bit since that time. So as a standard of comparison I assembled my final purchase from my early Wentworth buying binge. Fortuitously, it is the same 250 piece size as these inaugural puzzles from the new Victory company.

Packaging

I knew from having had the opportunity to see the website before the launch, and having chatted with Andrew, that in many ways the inaugural puzzles emulate aspects of the original vintage Victory brand, and in particular, its Artisan series. G.J. Hayter & Co. made puzzles of various levels of quality/price during its heyday in the 1930s. Its best ones – Artisan and Super-cut – were packaged in distinctive gold boxes that did not have a picture on the cover. That gold packaging became its hallmark of quality, and many of Hayter’s competitors copied that packaging for their own premium quality series and called them their Gold Box puzzles. (The name Victory had been copyrighted; the gold-box packaging couldn’t be copyrighted.)

Since the new company is modeling itself as a revival of the old Victory brand I was surprised when my puzzles arrived that they were packaged in black boxes. (I was less surprised that the boxes have pictures on their covers since that has become a strong expectation from most jigsaw puzzle fans.)

Basically, the new Victory company’s packaging is similar that of Wentworth’s, as well as what puzzlers expect from premium-quality cardboard puzzles and modestly-priced wooden ones. They are attractive, sturdy, good-quality cardboard boxes. The packaging for both Wentworths and the new Victorys also includes a cloth drawstring bag inside the box to protect the pieces from jostling and loss. That tends to be a feature only included with premium-quality thicker wooden puzzles.

There are two features that distinguish the new Victory packaging from Wentworth’s. The first is that inside the box is a cardboard stand designed to hold the box cover at a convenient angle for those puzzlers who like to use the image for reference during their assembly. More relevant for me is that although their puzzles assemble to nearly identical sizes, Victory’s boxes are much smaller than those of Wentworth (but are still sufficiently large that putting the pieces back into the box isn’t a challenge like it is with some companies’ packaging.) In fact, I estimate that the Victory boxes are about one-half of the volume of Wentworth’s. For someone who has limited storage space (and is there a puzzler who doesn’t?) that is a very nice feature.

Thickness of the puzzles

Both Wentworth and the inaugural release puzzles from the new Victory company are made from 3 mm thick (about 1/8th inch) medium-density fibreboard (MDF). For at least 20 years Wentworth puzzles have been made from that material. In fact, Wentworth was the first jigsaw puzzle-maker to use it instead of plywood, which must have seemed like a radical innovation at the time. I’ll go into more detail about MDF as a material later, but first I want to discuss thickness.

The thickness of wood puzzle pieces is the most obvious feature that distinguishes higher priced laser-cut jigsaw puzzles from their more standard-quality counterparts. It is true that high quality images and cutting designs can be found in puzzles of any thickness, but thicker puzzle pieces give the assembler a much more luxurious tactile experience. For me, that one factor makes a big difference in how I experience this hobby. However the extra thickness also makes puzzles quite a bit more expensive.

In general, companies that aim to make premium puzzles, and who are competing with each other on the basis of highest quality rather than price-cutting, make them out of either plywood or MDF in the range of 5, 6 or 7 mm thick (6 millimetres is about 1/4 inch.) They also tend to have more extravagant packaging to emphasize their “heirloom quality” but their rich tactile experience is what really makes them premium.

Puzzles that are 3 or 4 mm thick with more frugal packaging like these come from companies that are competing with each other more on the basis of price than higher quality. They aim to appeal to budget-conscious wood puzzlers, as well as attract cardboard puzzlers to pay a higher price to give wooden puzzles a try. (I don’t know why it is, but as a very general rule the 3 to 4 mm thickness is very common for laser-cut puzzles made in Europe and Asia, and North American companies are more inclined to compete in the 5-7 mm premium-puzzle marketplace.)

Personally, I really like that tactile experience and am able to occasionally pay for the incredibly rich feel of the thicker laser-cut puzzles, and even the occasional even-more-expensive hand-cut ones. But my budget requires me to consider them to be a special treat. Purchasing thick premium puzzles is a luxury that I can occasionally give to myself – the mainstay of my wood puzzle hobby (addiction?) is currently a search for high-quality frugal alternatives.

Only a few days after the new Victory company announced their launch in September, Wentworth made a major announcement: They were henceforth going to make their puzzles out of 4 mm MDF, beginning with this year’s new Christmas releases. That is 33% thicker and will give their puzzles an proportionate change in the feel of their pieces.

I doubt that the timing of those two announcements was related: My guess is that Wentworth’s transition plans had been in the works for some considerable time. But it will be very interesting to see how the new Victory company, or for that matter Unidragon and the many other makers of 3 mm puzzles will respond to this significant new challenge from the industry giant Wentworth. I expect that there will be many announcements made after the Christmas-rush season is over.

[Note: the Wentworth comparison puzzle for this review is with the old 3 mm thickness. At the time of this writing, Wentworth is still selling off its existing stock of puzzles that were made in that size before their introduction of the new standard.]

Material - MDF (medium-density fibreboard)

Like Wentworth and many other puzzle companies, including very high-end ones like the Canadian company Stumpcraft, this inaugural release of Victory Wooden Puzzles is made from medium-density fibreboard (MDF.) MDF is an engineered material made by combining wood fiber and glue under immense pressure and heat. It is made from wood fibres that would otherwise be a waste product, which makes it environmentally friendly. MDF is also resistant to chipping and delamination, and since it has no knots it is arguably a better substrate than most grades of plywood for glitch-free laser cutting. Probably most important, it is far less expensive than the very high quality hardwood plywood that is needed to make good puzzles.

MDF comes in a range of degrees of density and hardness, and it can be made from wood fibers from different species of trees. Because of their volume of production I suspect that Wentworth uses a proprietary MDF specifically designed for making jigsaw puzzles that is specially manufactured for them to the company’s specifications. As a small start-up company, the new Victory company has to buy MDF from suppliers that is made for the manufacture of a variety of types of products.

I don’t have a hardness testing tool but my impression, based on appearance, feel, and the sound that it makes when scratched while on a resonant surface, is that Wentworth’s MDF is harder and denser than that used in Victory’s inaugural puzzles. As shown in the above photo, the back of the Wentworth looks smooth and shiny while the back of the Victory puzzles are not reflective and they look more fibrous.

I had tiny chips of MDF flake off from two of my Victory puzzles, mostly from the back, and didn’t have any such chips from the Wentworths. But at least part of the reason for those chips was the very fine details in Victory’s cutting of figural pieces and connectors. I was able to glue some of them back into place and the others did not significantly affect my enjoyment of the puzzle. But that does suggest that the inaugural Victory puzzles will be subject to more wear over the years than Wentworths.

I also had one large chip that appears to have been caused by an interior delamination of the materials; more about that below under Customer Service.

Image selection

As the oldest and largest maker of laser-cut wooden jigsaw puzzles, Wentworth has a huge selection of puzzle designs available, reflecting a similar range of mainstream artistic styles as the large cardboard jigsaw puzzle-makers. They currently have 564 images in their catalog, and most of their puzzle images are available in various sizes of puzzles. Further, the company offers a service in which individuals can order custom-made puzzles made from artwork that they submit.

The new Victory company, of course, can’t match that selection (and neither can any other wood puzzle-maker.) As I write this about 2½ months after their launch, Victory’s products are still limited to their 10 inaugural puzzles, but those do show that the company intends to cover a range of artistic styles. The 10 include four commercial illustrations, five fine art paintings, and one example of kitsch art (Friend in Need, which is one of the classic dogs-playing-poker images) that seems out-of-sync with the others.

While Vincent Van Gogh’s Café Terrace at Night is a painting that many other companies have also used for their jigsaw puzzles, Victory seems to be the only source for puzzles with the other 9 images. For a short time their website showed two more puzzles with contemporary style artwork as “coming soon” but they were removed when the company began featuring its pre-Christmas promotions.

I suspect that most people choose their puzzles primarily based on them having artwork that appeals to them personally, and that puzzle companies make puzzles based on their anticipation of their customers’ tastes. Victory seems to be seeking to develop a clientele that is into relatively recent fine art (from impressionism to modern art) and well-executed commercial illustration.

Appreciation of art is a very personal thing. I suppose that the styles of artwork in the company’s future offerings will be determined by what types of puzzles their customers buy. Initial indications are that they will continue to have many images that I will like.

Printing

Modern printing technology is vastly improved over that which was used for the vintage Victory puzzles made by the Hayter company. The new Victory company and Wentworth both print their images directly onto the MDF using UV printers. This state-of-the-art printing technology is being adopted by many puzzle-makers in lieu of the traditional method buying professionally printed images or printing onto paper and then gluing the paper onto the wood.

As I understand it, with this technique the printer places special ink onto the substrate (in this case the MDF, or more accurately, onto primer that has been applied to it) and then intense LED ultraviolet lights immediately polymerize the ink, drying and adhering it to the substrate. Because the microscopic dots of wet ink do not have time to soak in or spread out UV printing enables very fine detail. UV inks also have a higher proportion of pigment to carrier material, enabling more intense colours, and the results are resistant to fading over time. It is also more energy-efficient than conventional printing methods, and it does not out-gas sometimes-toxic solvent compounds, making it an environmentally-friendly technology. If you want to learn more, here is a good introductory article about UV printing.

The appearance of both companies’ printing seems roughly equivalent and is of very high quality. Both are capable of rich, vibrant colours if that is what is in the artwork (as above) and both have low-glare finishes. Victory has a rather uniform satin-like sheen, while the Wentworths’ have reflectivity that ranges from matte to semi-gloss with the amount of sheen related to colour intensity. In The Red Vineyard at Arles, for example, white is the least reflective colour, and dark green and dark red are the most reflective. This gives a slightly richer look than that of Victory’s printing of the similarly colour-intense Van Gogh painting Café Terrace at Night, but the Victory puzzles have less reflectivity overall which is easier on the eyes during assembly. (Sorry! I cannot get a photograph to adequately convey the reflectivity differences that my eyes can see.)

Cutting design part 1 – the matrix of Wentworth puzzles

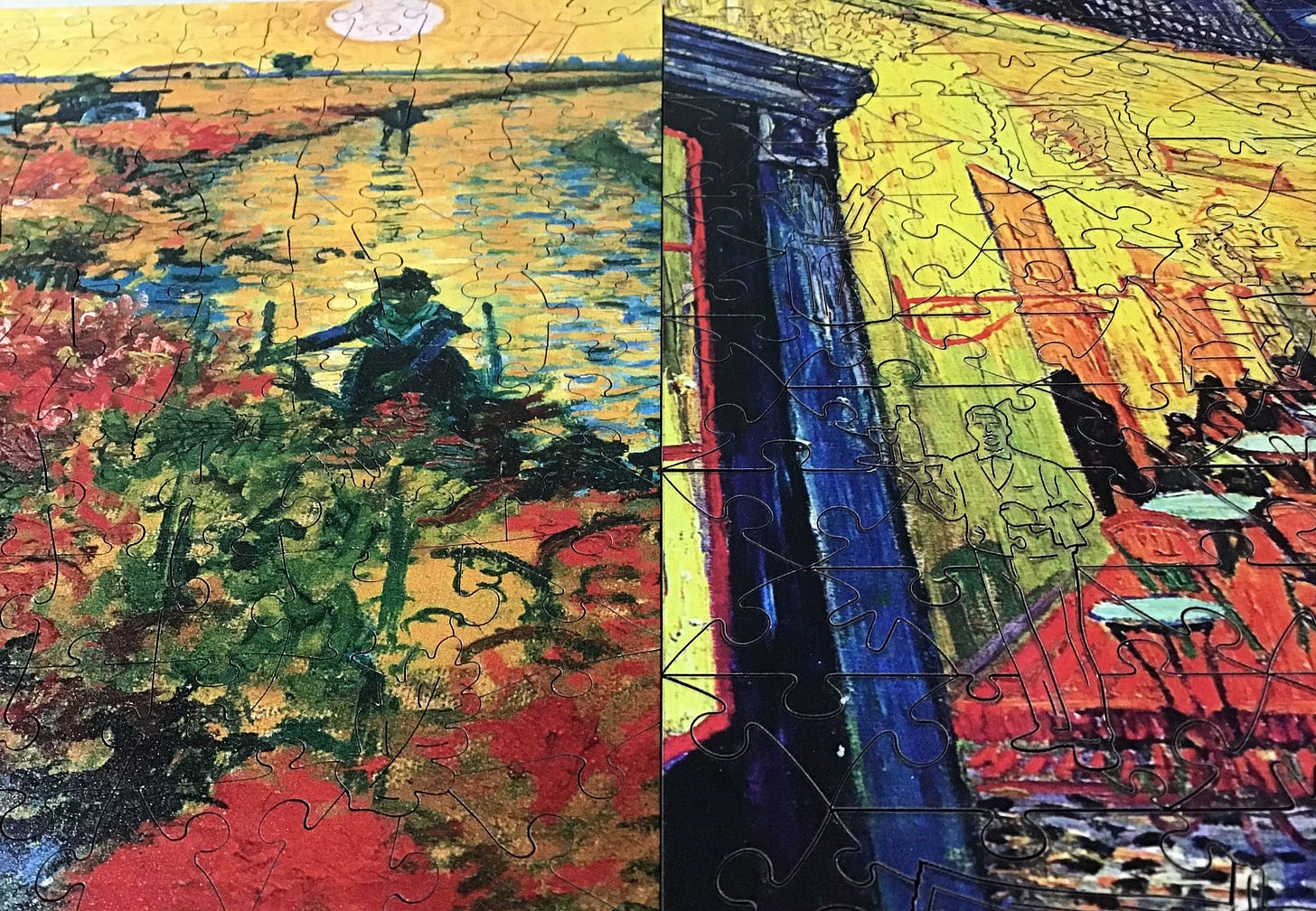

In my (humble?) opinion, Wentworth had more interesting cutting designs for their background non-whimsy pieces in its earlier years than they have now. Back then, although their figural pieces were very crude their non-whimsy pieces had a flowing, random-cut feeling to them. An example of that is the cutting of After the Hunt (see above photo) which I reviewed here. It was probably designed around the turn of the millennium. The above photos compare that cutting to the cutting of The Red Vineyard at Arles.

I can tell both from my memory of the three current Wentworth puzzles I assembled several months ago and from current images on the Wentworth website that the cutting of The Red Vineyard at Arles is a house style for the company, used in almost all of its puzzles. They do offer “extra hard” puzzles with other types of cutting, but this is the style they routinely use for their regular puzzles.

Basically their standard cutting is a gently crookéd or curving grid (or ribbon) pattern. It creates four-sided pieces that have one rounded knob connector on each side. In other words, it is the same type of cutting that is almost always used for die-cut cardboard puzzles. Because the grid matrix is cut parallel to the puzzle’s rectangular outer sides, border pieces are usually easy to recognize. That makes connecting the edge pieces first a good way to begin assembly.

Regular Wentworth puzzles always include 15-20 rather simple figural pieces in their 250 piece puzzles. Most of them are stock ones from the company’s collection of pre-drawn ones. The cutting designer overlays them onto the grid and the shapes of the pieces adjacent to the whimsies are adjusted to avoid making ones that are significantly larger or smaller than the puzzle’s average piece-size.

This Wentworth house style of cutting is identical to the cutting style that G.J. Hayter used so successfully beginning in the 1930s for the old Victory brand’s hand cut “Artistic” Gold Box wood puzzles. For Hayter the reason for that cutting style is easy to understand. It is the fastest and most efficient way to hand-cut jigsaw puzzles with a scroll saw. But that factor should matter far less for laser cutting, which is done by a computer guided machine.

The transition away from free-form cutting of the background matrix to this simpler style was probably a choice that Kevin Preston, the founder of Wentworth Wooden Puzzles, made so that assembly of his puzzles would be comfortable and familiar for people who were introduced to jigsaw puzzling by assembling cardboard jigsaw puzzles (i.e., the vast majority of jigsaw puzzlers.) His goal was to win over a significant segment of that market to either switch to wooden puzzles or to add his puzzles into their mix as an occasional premium quality splurge.

With this cutting the main differences from what such puzzlers already enjoy with cardboard puzzles are the durability and tactile experience of the wooden material and the novelty of having figural pieces. The heft and feel of 3mm MDF is still a considerable upgrade over the feeling of cardboard, and they have nothing like even simple whimsies in that material.

The relatively modest level of challenge from this style of cutting pattern might also appeal to experienced wood puzzlers when they want an easygoing enjoyment of image development rather than a higher degree of challenge.

In the context of having such a formulaic cutting style, the degree of difficulty any given puzzle presents is primarily determined by the image. To what extent does it give the assembler clues? Experienced puzzlers quickly learn to recognize which images give lots of clues, and which ones would be more difficult. They then can make an informed decision about what puzzle to choose to give them the kind of experience (on a spectrum of fun to challenging) they want to have when they pick a puzzle.

This traditional cutting design doesn’t take advantage of many of the opportunities that wood and laser cutting offer, but I can’t argue with Wentworth’s choice of this rather simple clichéd approach. They have been using it for a long time now. Add in affordability, a large selection of attractive images, and reliable technical production and very good customer service, and this cutting strategy has made Wentworth the largest and most successful of all the of the world’s wooden puzzle-makers.

Cutting design part 2 – the matrix of the new Victory puzzles

Perhaps as a tribute to the original Victory brand, or alternatively, learning from Wentworth’s great success, the new Victory company’s inaugural puzzles also follow the basics of this design strategy. However its cutting designer Aidan Knowles has brought some very interesting twists and diversity to this tried-and-true formula.

Victory is one of the companies that shows its cutting designs on its website. (By the way, that is a feature I very much appreciate. I want to select my puzzles carefully when buying, and I consider cutting design to be at least as important as the image in determining whether I will enjoy assembling a particular puzzle. And I am very good at forgetting what the cutting design is like by the time I assemble the puzzle.) From Victory’s website I can see that most of their inaugural puzzles follow a variation on that same cutting design strategy except with refinements that take much better advantage of laser-cutting capabilities.

Six of Victory’s inaugural puzzles are cut to create a fully interlocking matrix that has triangular pieces instead of four-sided ones (see above photo.) In one sense, the cutting of these six is even more formulaic than Wentworth’s. Their major cutting lines are not straight, but are a shallow low-frequency sine-wave interrupted by connectors that make the matrix pieces fully-interlocking. But instead of having only one shape of connector like most of Wentworth’s, Aiden’s designs use two or more including occasional use of a distinctive connector related to the company’s name that looks like fingers giving Winston Churchill’s famous “V for victory” sign.

Another feature of this matrix design is that most of the outside border is comprised of the long straight sides of triangular pieces interspersed with the tips of triangles, and all four corners of the outside edge are the tips of two triangular pieces. This makes it impossible to begin assembly by doing the border first and then working inward, thus making the puzzle more challenging.

Such disguising of corners and edge pieces is also sometimes done with grid cutting in cardboard puzzles and by Wentworth – for example, The Red Vineyard at Arles has all four of its corner pieces and six other edge pieces disguised. But grid cutting can usually only disguise a few of the edge pieces. This Victory cutting design hides almost half of them.

But, as usual, the primary factor for determining puzzle difficulty is still whether or not the image is helpful in providing clues. In the case of Café Terrace at Night the image was very helpful, by having several straight lines and areas of distinctive colours and texture. But I suspect that all of the other five puzzles in this inaugural offering that use this cutting style would have been more challenging for me.

Two of my three puzzles had a different matrix cutting style, suggesting that the new company’s cutting designs are not going to be as purposely predictable as Wentworth’s.

The above cutting design of The Flapper – Life 1922 was more geometric, with its matrix cutting mostly at a 45⁰ angle from horizontal and vertical. Besides triangles the pieces are parallelograms, rhombuses, squares and other shapes. The overall effect is very reminiscent of the Art Deco fashion that was all the rage in 1922 and it was a reaction against the soft, sinuous lines of Art Nouveau. This angular, symmetrical cutting design is therefore much more suitable for this image than slow sine-wave cutting. It does create straight-edge border pieces which should aide in assembly, but the puzzle’s image has a homogeneity around its border that counteracts that advantage. On balance it presents a similar level of challenge for assembly.

The matrix cutting for Vintage Poster San Francisco is a grid of square-like pieces, which makes beginning by starting with the border very possible, and assembly easier. But the puzzle is made more interesting by the use of intricate cloud-layer shaped connectors on most of the horizontal lines. The other connectors, besides the relatively few V-for-victory ones, are round knobs reminiscent of cumulous clouds. Puzzle designer Aidan Knowles is very familiar with San Francisco’s infamous cloud-banks and fog: he recently graduated from the California College of Arts, which is located in that city.

I noticed that in Café Terrace at Night Aidan had placed a beer glass figural piece right along the vertical line that separates the yellow-lit area from the darker street, creating a colour-line cut that made finding the adjacent piece more difficult. Aidan seems to have a natural flair for being both a thoughtful and tricky cutting designer. I got a peek that shows more cutting diversity is on its way from him. Two puzzles were posted briefly of the website as “coming soon” and one of them features both a pop-art style array of frog images painted by Aiden and a frog-shaped tessellated cutting pattern.

Cutting design part 3 - figural pieces

The inclusion of whimsies (aka, whimsies, silhouettes or figurals) adds a novel fun element to wooden puzzles and (for better or worse) it usually makes assembly somewhat easier. The technique goes back to about the turn of the 20th century. When puzzles are hand-cut including them significantly slows down the speed at which puzzles can be made and it adds a risk of ruining the puzzle being cut, so they greatly added to the cost of a puzzle.

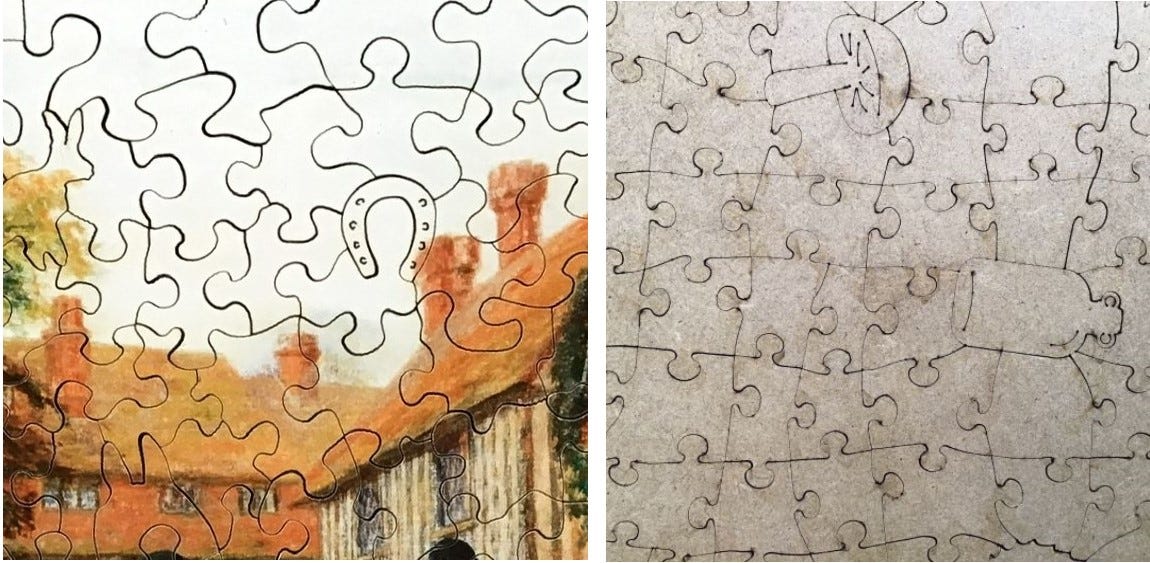

Cutting figural pieces in vintage hand-cut puzzles was difficult so they were therefore usually very simple with fairly smooth lines; sometimes barely-recognizable silhouettes. When Wentworth was a new company its founder and designer Kevin Preston was not an artist, and the whimsies that he incorporated into his newly-invented computer-controlled laser-cutting of puzzles emulated those of vintage hand-cut puzzles he was trying to emulate; i.e., they were fairly simple.

In my experience, the bland edges of simple figural pieces are not as helpful at expediting assembly as intricate whimsies. The currently-available Wentworth puzzles are designed by artistically-trained specialists and their design for figural pieces are somewhat more sophisticated than the early ones, but many puzzlers have noted that the company continues to include relatively few, mostly fairly basic whimsies in their products.

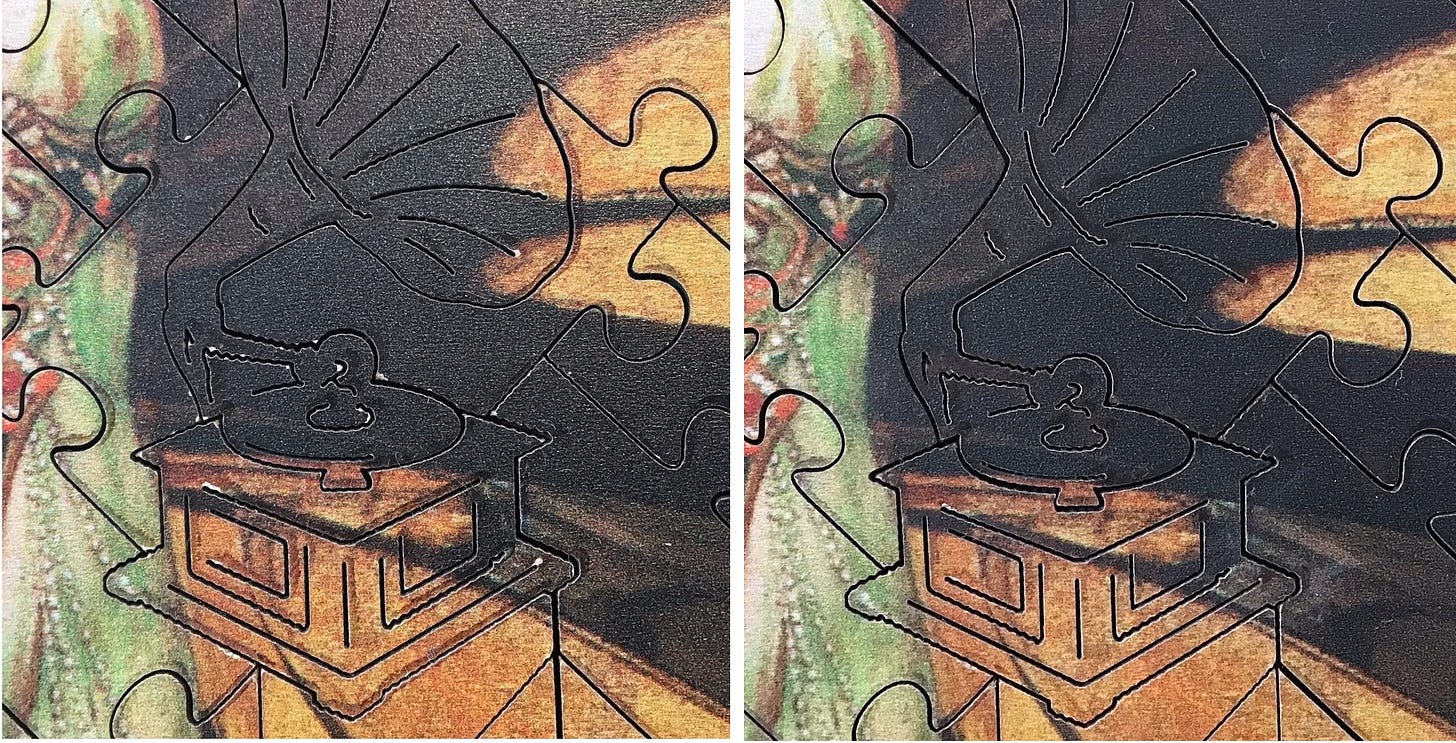

That is bucking a trend for laser-cut puzzles. Most other companies are increasingly populating their puzzles with more figural pieces than ever before, and are making them increasingly intricate. They also put more accent lines into their figurals so that each whimsy is, in itself, a miniature work of art for the puzzler to appreciate. The current trend is also to include multi-piece figures that are themselves like mini-puzzles, and sometimes individual whimsies relate to each other to create a scene or tell a story. Often it is only by turning the puzzle over after completion that the puzzler discovers such features as a secret delight.

Instead of the rather simple single-piece figural pieces that the vintage Victory had and Wentworth puzzles still has, Aidan Knowles’ whimsies follow this trend and are quite detailed. There are also more of them. While Wentworth has 15-20 single piece figural pieces in each 250 piece puzzle, my three Victory puzzles each have 22-24 whimsies, including 7-9 multi-piece ones. One of my Victory puzzles even has a set of pieces that collectively can be removed from the puzzle to make a 3D structure of a painting on an easel.

As with most jigsaw puzzle-makers, the figurals in Wentworth puzzles are not usually designed for specific puzzles. The company has a huge catalog of pre-designed whimsies that puzzle designers can choose from and re-use, and they select ones that seem to suit the puzzles image. In the picture above, the grapes, wine bottle and wheelbarrow match the image of Wentworth’s The Red Vineyard at Arles’ image very well, but the maple leaf, flying duck, mushroom, and oak tree seem only to have been chosen because they relate to the month of November.

The figural pieces in each of the new Victory company’s puzzles all fit their image perfectly, but that might partly be because they don’t yet have an existing pool of whimsies to choose from. There is re-use of some of them in this inaugural set of ten; for example the tubes of paint and the elaborate 3D easel are also used with other puzzles with fine art images.

As with most vintage puzzles, the figural pieces in Wentworths might be oriented in any direction; they are not necessarily consistent with the orientation of the image. The ones in the new Victory puzzles are all upright. That is an attention to detail that I appreciate.

The current fashion for intricacy in whimsy design is not without its drawbacks. Finely cut pieces, and the adjoining non-whimsy pieces that interface with them, can be more fragile and subject to damage over time. Also, the accent lines can be very effective at enhancing the appearance of the individual figural, but the black laser-cuts can add busyness that detracts from the appearance of the image on the puzzle. On the other hand, depending on how you perceive it, the presence of cut-lines can also sometimes enhance the view of the overall puzzle. This will be discussed in Part 2, in the context of my assembly of The Flapper – Life, 1922.

In summary, the cutting designs of Wentworth puzzles have a retro feel, with simple whimsies and a fully-interlocking interlocking grid matrix. In general this makes their puzzles easier to assemble and a comfortable transition from cardboard jigsaw puzzles. The cutting designs of the new Victory company also use a fully interlocking matrix, but theirs have more variety in their cutting and their whimsies are more intricate. I would expect that most people would find the cutting of Victory puzzles to be more interesting and challenging.

Teething problems

Wentworth has been making laser-cut wood puzzles for over 20 years. They have experienced operators running their equipment and good quality control. On the other hand, the Victory puzzles I am reviewing come from a newly established company, made before the company had even launched and before the staff were fully familiar with their new state-of-the-art UV printer and laser-cutting equipment. Not surprisingly, they exhibit some technical problems but fortunately they are minor, and I understand from Andrew Knowles that they have already been addressed. But since I encountered them in the puzzles I assembled I feel obliged to report about them.

UV printing should be very durable but in each of my three inaugural puzzles tiny chips of ink had occasionally flaked off along some of the cut-lines. These chips were very small and many people might not notice them in the context of the overall image. But for me they stood out in places where the exposed stark-white primer contrasts with dark parts of the image.

Andrew told me that they now know that although the UV light dries the ink immediately, it takes a few days for it to become fully cured and adhered to the substrate. They have adjusted their process to give the newly-printed boards the necessary curing time before they cut and disassemble the puzzles. They have not had chips in their more recent production.

Even before asking Andrew about this I had discovered my own do-it-yourself (DIY) fix for the chips on my puzzles. They are easily made invisible by darkening them up. At first I colour-matched with art pencils but I found that I could also get satisfactory results using simple graphite “lead” pencils. I learned that I didn’t even have to be very careful while doing this: The pigment from pencils adheres to the primer but does not easily stick to the nearby cured ink. The repair process was quick and simple.

Another teething problem that had a DIY fix and has already been resolved was that I had rather extensive smudging (not scorching) on the fronts of all three of my Victory puzzles. Smudging is a discolouration that appears similar to scorching but it isn’t caused by burning the ink. It is smoke from laser-cutting that has condensed onto the face of the puzzle near the cut-lines. It appears to be a fuzzy brown line that is adjacent or parallel to the cutting.

Laser-cutting machines are not simple “plug ‘n’ play” devices: They require careful adjustment and must occasionally be fine-tuned for optimal results. As I understand it, avoiding smudging involves both adjustments to the cutting settings and to the flow of the exhaust fans. It is a fairly common problem in puzzles made by new laser puzzle-makers as keeping the machines operating properly is a skill that the machine operators learn through experience.

Back in May I made an enquiry to the Facebook group with regard to another puzzle that had this problem and reported about in this review. I learned that different people have different tolerance levels about for smudging. A few consider it to be totally unacceptable in a puzzle they paid for, but more consider it to be a minor and acceptable flaw, especially if the puzzle comes from a small artisan workshop or a new puzzle-maker. I found myself sharing the latter perspective for that puzzle and for these.

I also figured out a way to clean the puzzle of their smudging and found that my enjoyment of the puzzles outweighed the inconvenience of having to do so.

Of course I would rather have new puzzles always arrive in absolutely perfect condition. But as with covering up the ink chipping I found that I rather enjoyed this cleaning process once I got into it. (I wish I could bring myself to feel that way about cleaning my apartment!) It felt like I was doing art restoration, similar to what conservators do to bring back the original colours from old paintings by removing the varnish that darkens them over the years (except that I use much smaller cotton swabs than they do.) The process is quite easy, dipping a cotton swab into 70% rubbing alcohol and gently rubbing where there were visible smudges. I could tell by the grey colour on the used cotton swabs that that the alcohol was only removing smoke residue, not ink.

As with the ink chipping, when I asked Andrew whether they had resolved this issue with regard to their current production he told me that they had. It does not occur in their current production.

One very common problem that many laser-cut puzzle companies have is scorching on the back-sides of their puzzles. I know from the various discussions about it in the Wooden Jigsaw Puzzle Club group on Facebook (a wonderful source of information and community!) that experienced puzzlers consider this backside scorching to be normal. It isn’t really a flaw because it does not affect assembly or appreciation of the puzzle’s artwork, and it is so common because the puzzle companies know that most people will never turn their puzzles over and see it anyway.

A few of companies (like Stumpcraft and Unidragon) have solved this problem and apparently how they do it is a carefully guarded trade secret. Most companies, including highly-regarded makers of premium puzzles like Artifact Puzzles, haven’t been able to resolve it. I have gotten used to seeing back-side scorching when I turn most of my laser-cut puzzles over. In my reviews I don’t consider backside scorching it to be a flaw no matter how extensive it is, but a puzzle-maker does get extra brownie points if/when they are able to avoid or minimize it.

Wentworth has only very minor backside scorching. Victory’s is much more visible but I consider its extent to be typical of most company’s products, and less than many of them. I didn’t bother to ask Andrew if they have resolved this issue.

Scorching on the front side of the puzzle is another matter. Scorching is where the heat from laser-cutting discolours the ink near cut-lines. This discolouration is permanent and cannot be cleaned off. I had some minor scorching in a few places on the front of The Flapper – Life, 1922 where whimsies had close-together accent cutting, but even by looking for it I couldn’t find any on the other two puzzles. That same puzzle was also the one that had the worst scorching on the back-side. Andrew confirmed that my Flapper puzzle must have been from one of their earliest batches because they figured out fairly zoon how to adjust the setting of the laser-cutter both to prevent front scorching and lessen it on the back.

Front-side scorching is another issue that has had discussion in the Facebook group: Should one complain to the company and expect some form of redress? Again, opinions are mixed. Most responses said that they do consider this to be a flaw but that they would only complain to the company if it significantly interfered with their enjoyment of the puzzle, and that they are inclined to cut some extra slack about this for new puzzle-makers. I consider my scorching on this one puzzle to be minor and to have been greatly outweighed by the enjoyment that the puzzle gave me. I would not have complained to the company about this if I had bought the puzzle instead of having received it as a gift.

Customer service

The extent that a company is willing to back up their products with good customer service can be very important given the cost of wooden puzzles. Customer service issues are a fairly common topic in the Facebook group, but I suspect, not as often as customer service is needed.

People who like a company and want to support it would be reluctant to report good customer service to others online because it draws attention to the fact that they had a problem in the first place. Only when they are upset about the lack of response to a complaint, or an unsatisfactory response, do they initiate telling others about an unsatisfactorily-resolved problem. When they do, others in the group respond by recounting their own experiences with the company (good or bad) and with suggestions about how they might get to a more satisfactory resolution.

Personally, I haven’t had much need to test companies’ customer service, possibly because I avoid companies that have a bad reputation for either their products or for bad customer service. That at least partially explains why all of the reviews that I have posted either here or in the group have been positive ones.

The two times when I have needed to bring a problem to a company’s attention I have gotten a very satisfactory response. But, as I explained above I didn’t want to draw attention to the initial problem by complementing the customer service so I haven’t mentioned that in my reviews. One of those incidents occurred very early in my wood puzzling before I got engaged with the online puzzling community. The other was a missing piece in a puzzle that I did report about here, but I was very promptly given a replacement piece.

In this case I will acknowledge a satisfactorily-resolved complaint. Café Terrace at Night had a chip that showed fairly prominently on the front of the puzzle. I checked and double-checked my puzzle-board,, and the box, and the bag, looking for the missing chip. If I had found it I could have glued it back into place and the problem would have been solved. The chip was nowhere to be found so I figured that it must have come off before my puzzle was packaged.

I sent an e-mail about this to the company’s general contact address with that information and with above photo, as well as another photo to show its context and to ask if I could get a replacement piece. I got a very quick response from Andrew. They didn’t yet have a system in place yet for replacing individual missing or damaged pieces because such an issue hadn’t yet arisen. He said that they would send me a full replacement puzzle.

I replied suggesting that he hold off on that because we had a phone call scheduled for a few days later anyway. (It was the one in which I got the information from him about issues that had learned already been resolved that I reported above under Teething Problems.) Over the phone I told him that I would still be happy just getting a replacement piece, but that if they were going to send a piece in the context of a whole new puzzle this might be an opportunity to provide me with a third puzzle for this review. That is how I got Vintage Poster San Francisco.

From that discussion, and from another one that I had with Andrew, I am convinced that they are committed to building their company by giving their customers both excellent products and excellent service.

Since then I feel rather bad about having gotten another free puzzle on top of the two that Andrew had already sent me. (But, as you can see, I haven’t let that stop me from identifying the few shortcomings I found in these inaugural puzzles.)

Recently I applied my new-found skills in using coloured pencils for covering up tiny ink chips to disguising this larger wood chip. Can you find my repair in the following detail photo of Café Terrace at Night ?

Conclusions

I know from my discussions with Andrew that their ambition is to become a major manufacturer of wooden puzzles, not stay at their current scale as an artisan workshop. In this price range, and especially being a British company, that means that they are taking on Wentworth. So for this review I made Wentworth my standard of comparison.

I know that it is not fair to compare the inaugural offerings from a brand new company against the company that invented the genre of laser-cut wooden puzzles, has been making them for over twenty years, and leads the world is sales. It is very unfair, in fact. But this new Victory company met the challenge with flying colours!

They cannot match Wentworth in the number of different puzzle images that are available now of course, but the ones they do have are well-chosen and seem to focus on an artwork niche of high quality commercial illustrations and the always-popular fine art paintings. I am sure that there are many good choices and variety in styles yet to come. Currently they only have 250-piece puzzles available. I don’t know what various sizes they intend to have in the future, but in a message in the Facebook group Andrew said that 500 piece puzzles are coming, probably in 2023.

The quality of Victory’s printing and manufacture is comparable to that of Wentworth (i.e., excellent) and I like their more-compact packaging better. But where they really shine above the venerable industry leader is in Aidan Knowles’ brilliant cutting designs, which are very intelligent, modern and creative compared to Wentworth’s old-fashioned cutting style.

As discussed above, Victory’s current puzzles are more challenging than the equivalent rather formulaic ones made by Wentworth. That may or may not make them suitable for cardboard-puzzle people who are looking for an introduction into the world of wooden puzzles. But I think that people who are already Wentworth fans will find these Victory ones to be an improvement over the Wentworth formula, as will people like me who are looking for a satisfying frugal alternative to intersperse with assembling thicker more-expensive puzzles.

These inaugural puzzles show that the artistically-trained Aidan Knowles has a real talent for this rather esoteric medium of creative expression. Making puzzles in a larger size, where the presumption can be made that buyers are already experienced wood puzzlers, will give him more latitude to expand his bag of tricks for making assembly more challenging.

In these puzzles I got the feeling that Aidan was holding back, for example by not using more colour-line cutting or by making one that did not have a grid-pattern for its non-figural pieces. (What is called “random cutting” isn’t really random, but in my mind it is more interesting in itself, and it also opens up opportunities for various techniques that can help disguise matching pieces with their adjoining ones and thus create for more challenging assembly.) This essay by vintage puzzle collector, conservator, and historian Bob Armstrong traces the history of various such techniques.

I am not questioning Victory Wooden Puzzles company’s choice of restricting their inaugural puzzles to relatively simple ones in 250 piece size. Based on the used Wentworth puzzles that come up for auction that appears to be by far the most popular size (at least, for puzzles that people choose not to keep!) so that is where the biggest market is. But I do look forward to seeing what their 500 pieces ones (for me at my current level of experience the puzzle-size sweet spot) will be like.

Now that Wentworth has announced their future puzzles will all be 4 mm thick the new Victory Wooden Puzzles Company and all other makers of 3 mm puzzles face a challenge. I mentioned above how I feel about the importance of puzzle thickness to the quality of the puzzle-assembly experience. I look forward to seeing how Victory and the other companies respond to Wentworth having thrown down that gauntlet in front of their competitors.

If this Conclusions part of my review seems to be focusing on what I hope to see in the future from the company I want Andrew and Aidan and their team to take that as a compliment. I really do like what I see in what they have already done. Their quality and creativity is very impressive and I expect to see great things from them in the future. The fact that I want bigger and more challenging puzzles from them proves that I know they will make puzzles that I will love!

Part 2 of this review includes my assembly experiences with all four of these puzzles and my usual miscellaneous research findings and musings inspired by them. You can read it here.

I can say that when they posted about their beginning venture I was quick to jump on board in buying the puzzle they said was a homage to the original Victory and the times they were created, i.e. their "The Flapper" puzzle. I found the puzzle cut intriguing and different, and their whimsies fun. But, I was not happy with the shadow effect, which perhaps is what you mean by the laser burning on the front, I'm not sure. To me it looked like pencil lines that the laser cutter was supposed to cut along, but missed by a smidge, and thus there was a shadow mirroring the cut lines, especially in the lighter colored areas. I have purchased many (like over 100 at least) of laser cut puzzles of various brands in my collection and I found it not a usual thing at all. So undesirable that I put them on my no buy list... but changed it to a caution note because their customer service communication about the issue was at least attempted. I believe they offered me a small discount on my next purchase... which I have a desire to purchase the same puzzle again in hopes that they would have fixed that issue, because I wanted that particular homage puzzle from their introduction to the puzzling world in my collection, but I wanted it to be better without the faults I had in my first puzzle. So, I may give them another chance after they've been in production and works out their kinks, we shall see.

Well done, Bill. Of your written material today, I enjoyed the Conclusions section best. In fact, I agree with you conclusions. If I buy myself a laser-cut wooden jigsaw puzzle, I think I will try one of Victory's offerings. Of the puzzled pictured today, I best liked "Café Terrace at Night." Though I am not certain, I think your coloured-pencil repair job may have been on that puzzle's one or both of the orangey brackets extending from the yellow wall. In any case, it was fun trying to decide about that.