45. Artifact puzzles; an in-depth review

Artifact Part 2 of 3: A deep-dive review of the puzzles made by the Artifact Puzzles company. (about 7200 words; 11 photos)

[Note: As always, except as a paying customer I have no affiliation with Artifact Puzzles and do not receive any proceeds from their sales.]

This is the second of a three part posting about Artifact and Ecru puzzles, and is itself a follow-up to my posting #11 about Woman with a Parasol. That posting is about a 357 piece Artifact-branded puzzle with an image painted by the impressionist artist Claude Monet and the posting was primarily couched as a review and commentary about that single puzzle. I was quite favourably impressed.

I now have much more experience in assembling high end wooden jigsaw puzzles, including five more made by Artifact that were designed by five different designers. They are:

Rosso Angelo (Artifact) 228 pieces designed by Kathryn Flocken

Shiba Benten Pond (Ecru) 89 pcs Amy Tang

Armond Point Unicorn (Artifact) 101 pcs Jef Bombas

Fisherman’s Cottages (Ecru) 158 pcs David Figueiras

Van Gogh Landscapes Double-sided (Artifact) 150 pcs Tara Flannery

Based on these additional small puzzles, together with Woman with a Parasol, I now feel I have sufficient experience and understanding to write this in-depth review of Artifact-made puzzles in general.

This report is Part 2 of three parts. Part 1 was an essay about the history of the company that primarily features its founder, Maya Gupta, and Part 3 will have information and assembly walkthroughs (below a spoiler alert) of the five additional puzzles that were the basis for this review.

Index for this part

Introduction and evaluation standards

Selection of images

Selection of sizes and cutting designs

Cutting designs

Wood

Printing

Cutting execution

Packaging, fulfillment and shipping

Miscellaneous and conclusions

Introduction and evaluation standards

It seems like just about every laser-cutting puzzle company calls their jigsaw puzzles “premium” or “heirloom quality” but that is often just meant to distinguish themselves from cardboard puzzles.

Most of the puzzles that are made in laser-cutting factories and workshops around the world compete against each other in a tough marketplace on the basis of price. To keep their costs down they are usually 3 millimeters thick, and often they re-use figural pieces or even whole cutting designs for multiple puzzles. They often have very basic packaging and sometimes they use AI-generated artwork. The prices for such basic-level wood puzzles are considerably higher than for die-cut cardboard jigsaw puzzles of comparable size, but still lower than other wooden jigsaw puzzles which do not take as many shortcuts to keep their prices rock-bottom low (for wood puzzles.) Many of the puzzles in this basic category are manufactured in giant laser-cutting factories in China.

But because wood does enables much more sophisticated cutting design (including but not limited to the inclusion of figural pieces) than die-cut cardboard one, and they are indeed much more durable, such puzzles can be an inexpensive introduction to what wood puzzles have to offer. In that context I suppose, in the world of jigsaw puzzles they indeed can be called “premium” or “heirloom quality” but in the world of wooden jigsaw puzzles they are bottom-rung and have many missed opportunities and shortcomings.

Then there is a mid-range step up above that basic level where companies make do not make so many quality compromises to be able to be among the cheapest wooden puzzles available. Ways of upgrading quality include making the puzzles 4 or even 5 mm thick, and having better printing and packaging or better cutting quality, and better packaging. But in this tier they still have technical flaws, missed opportunities or other shortcomings. Within the lower- and mid-priced tiers all of the makers have some strengths and weaknesses and their prices are roughly in inverse proportion to how many weaknesses they have.

Artifact’s puzzles are not in either of those categories. A few laser-cutting companies are on an altogether higher tier where above-and-beyond excellence is the norm. In North America such puzzles are always 5 or 6 millimetres thick. As I have often mentioned in this newsletter/blog, extra thickness gives puzzle pieces a much richer tactile feel and turns assembly into a much more luxurious experience. But besides thickness they also have exceptional levels of design creativity (which includes variety in the types of challenges that their cutting delivers), “heirloom” packaging, and superior printing and fabrication.

Not all thicker puzzles are in this top echelon, but of those that are none have any significant weaknesses. Artifact has two grades of puzzles – its regular Artifact-branded ones and its higher-priced Ecru line which has tighter, less-prominent cut-lines and images with matte reflectivity. For reasons given below (under Cutting design and Cutting execution) I consider both lines to be in the same top-tier quality range that includes such exceptional companies as Liberty, Stumpcraft, Hidden Piece, Fathom, Mosaic and DaVICI. (There are certainly other makers, including some European ones (who make thin-but-very-artistic puzzles), that also probably should be in this tier but to date I have insufficient experience with those to classify them.)

Naturally, the premium tier of wooden puzzles sell for higher prices that reflect their added costs. They are made by companies that aim to appeal to customers for whom price, while it may still be important, is a secondary consideration. They are people who want to experience the best of what laser-cut wooden jigsaw puzzles have to offer. It is those higher prices that shape my expectations, and hence my standards for evaluation of their products. In this previous review of Hidden Piece Puzzles I included a long digression about my review considerations and standards for top-tier puzzles.

Personally, my budget situation is that buying puzzles from any of these top tier companies must be relatively infrequent so I need to shop carefully. A summary of my conclusions about Artifact and Ecru puzzles can be inferred from the following fact: While writing this review I ordered nine more of their puzzles.

Selection of images

People’s preferences for styles of artwork are personal. I know that I have my own preferences and biases with regard to styles of artwork and that I cannot assess whether any company’s selection includes pictures would appeal to you. But I can assess whether their catalog gives potential customers variety and enough information to make a good choice.

The puzzle artwork available from the various companies are partly shaped by the proprietor’s or art director’s tastes, but more importantly, by what styles of images prove popular with their customers. That in turn, is partly shaped by current cultural and artistic fashions among their customers’ demographic base. My guess is that the demographic base for top-tier puzzles tends more towards boomer-age customers (like myself) than towards millennials and Gen Z. But that said, the companies usually do want to offer something for everyone.

In general the number of puzzles that a company makes available is related to how long the company has been in business. Liberty Puzzles, which was established in 2005, is the top-tier company that has been around the longest (I consider Wentworth to be mid-range,) and they certainly do carry a wide variety of styles of artwork. They have probably offered well over 1500 different puzzles over the years but they have a policy of periodically withdrawing them from their catalog (sometimes permanently and sometimes only temporarily.) As I write this they have 580 puzzles available. Geoff Cota’s Fathom Puzzles is at the other end of the spectrum. It was launched in 2022 and at the time of this writing it only has 14 puzzles available (but they are all indisputably first-class quality.)

Artifact, founded in 2009, has the second longest longevity among the top-tier companies. Their current catalog has over 500 entries, although some of them are listed as currently being “sold out.” (You can get on a mailing list for notification when they are available but they warn that it may be a few months until the company makes them again.) Their offerings are well balanced between historic and contemporary fine art, and modern illustrations that tend to be on the fantasy and playful side. As a very rough generalization, the fine art puzzles might tend to appeal more to us boomers and Gen X, and the modern illustrations may have more appeal for millennials and generations Y and Z. Perhaps they really do have something for everyone.

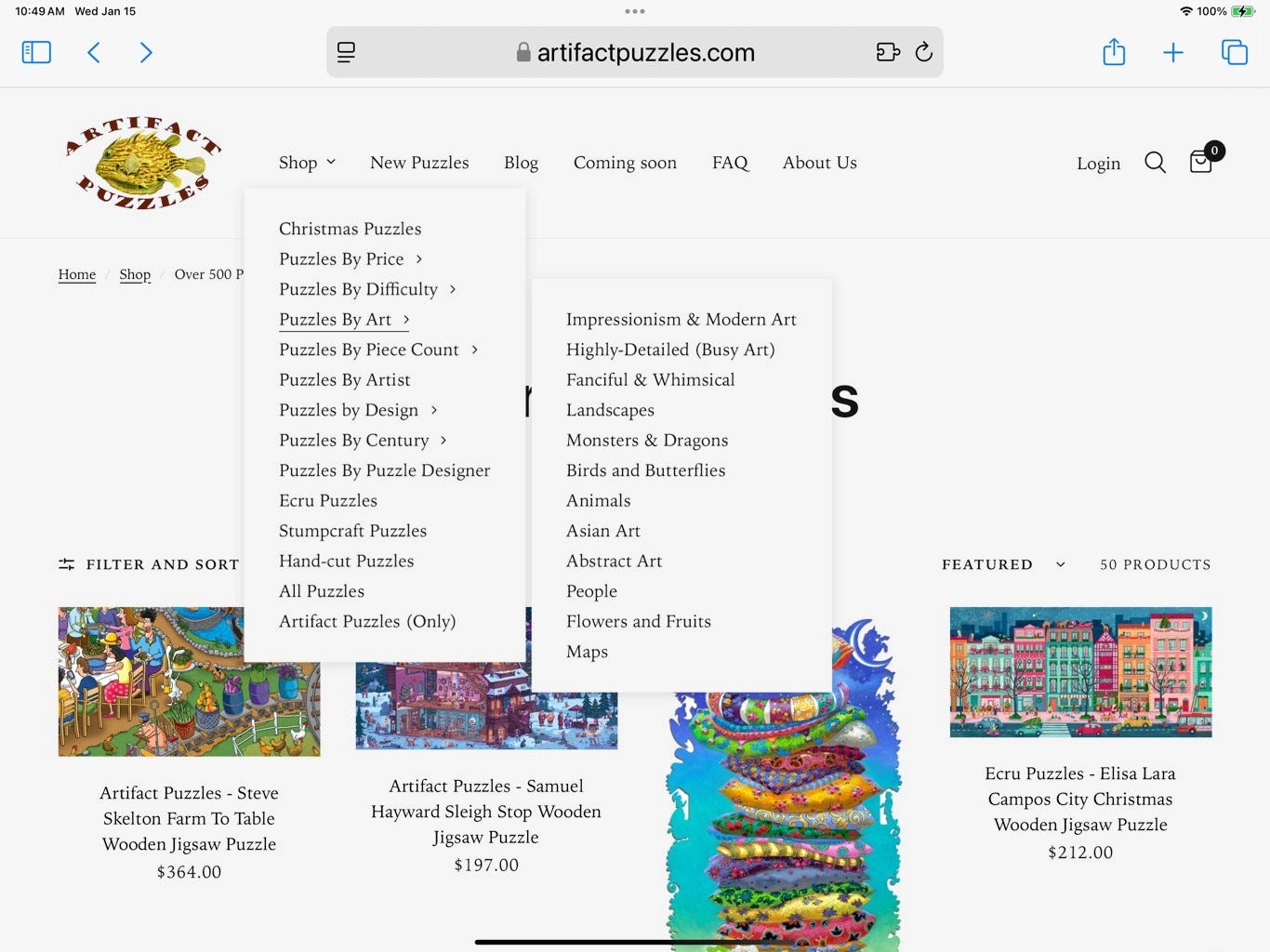

One risk from having such a large catalog is that there is so much to look through, especially if someone is leery of FOMO (fear of missing out) by choosing their purchases before having seen everything that is available. Fortunately, as with Liberty, the website provides some help here by having drop-down menus that enable shoppers to search for images by style of art, by artist, and even by century, as well as having some filtering capability to help narrow down the selections.

Since image is the primary factor upon which most people choose puzzles to buy, all of the top-shelf companies’ online catalogs do a good job of displaying their images and they often have the ability to zoom in to study the picture in detail. Artifact’s website itself does not have much zooming in capability but there is usually a close-up of part of the image. Also, the photos are fairly high resolution and can be enlarged using your device or computer’s viewing magnification if you want to see how much fine detail you can expect to see in the puzzle’s image.

Selection of sizes and cutting designs

All of the wooden puzzle companies offer a range of sizes of puzzles. This is usually most effectively measured by piece-count, since most of the companies cut their puzzles for adults up into pieces of a “sweet spot” of similar approximate size. The sizes of wooden puzzles can range from small “snack sized” ones to those that are well beyond the capacity of my puzzle board or table (as well as beyond my capacity for patience!)

Artifact’s biggest selection is among their smaller puzzles ranging from about 70 to 200 or so pieces, but because of their very large selection there are still many to choose from in the 200 to 500 piece range. At the other end of the spectrum they have four puzzles that are over 1000 pieces (which is a lot for a wooden puzzle) with two more coming soon. They even have one including one that can be built as a 2500 piece challenge.

Some companies make multiple sizes of puzzles that use the same image. They do that by designing a cutting pattern for the full size version of the puzzle, and then use similar cutting designs and some of the same whimsies for one or more smaller-scale and easier-to-assemble versions of it. This makes puzzles with desirable images available for people who cannot afford the full-size puzzle. Artifact does not do that. Its puzzle designs and images are tied to each other only come in the one size for which the cutting was designed.

The situation with regard to cutting design is similar to tastes in artwork – different people have different personal tastes with regard to styles of cutting and different degrees of difficulty. But the companies vary considerably with regard to the information that they provide in their catalogs for buyers to make their buying decisions.

Some companies, such as Hidden Piece, Palmaris and Liberty, routinely show you the full cutting design on their website, or at least, enough of it so that you can use your previous experience to assess whether its cutting style would appeal to you. Other companies do not want to deprive you of the surprise element inherent in discovering cutting tricks for yourself. Artifact Puzzles is at that end of the spectrum. They do not show you the cutting design but they do provide a text description of the cutting style, and in addition to photos of a few of the whimsies they show a small selection of its non-whimsy pieces.

Artifact’s difficulty statements range from “kind-of-easy,” through “average,” to “kind-of-hard” or “more difficult than average,” to “really difficult.” The difficulty descriptions are in the context of the puzzle’s piece-count, so as they explain on their website “a really hard 80 piece puzzle is still easier than an easy 500 piece puzzle!”

As with the artwork styles, while shopping on their website you can use a drop-down menu to help winnow your search to the amount of challenge that you want. In their individual puzzle’s descriptions for “average” difficulty and “kind-of-hard” puzzles they do not usually say whether its difficulty derives from a challenging image or from a challenging cutting design. But experienced puzzlers (wood or cardboard) learn to recognize the degree of challenge that different images present.

When Artifact self-rates a puzzle as “really difficult” it is likely to be because both the image and the cutting design provide an above-average degree of challenge, and the write-ups about the puzzle (as well as the customers’ reviews at the bottom of the page) will give some explanation as the what it is about the cutting that earns it that rating. Mind you, I don’t personally have experience with any really difficult or extra-large puzzles from Artifact, or anyone else for that matter. I have only been assembling wood jigsaw puzzles for three years now: I want to avoid frustration and am aware of the limitations in my puzzling ability and patience so I factor that in to my buying decisions.

On the other hand, I do sometimes want to do a puzzle that is relaxing (a euphemism for “kind of easy”) although even with those I want some degree of challenge. In my experience, all of the top-notch wooden puzzle makers earn their reputations by making puzzles with satisfyingly tricky cutting designs and they make puzzles that are more challenging than their more run-of-the-mill counterparts; their difficulty self-assessments should be taken in that context. The five puzzles that I am basing this review on are all rather small (and therefore inherently easier) but are rated by Artifact as average or harder than average for their size. They all achieved a perfect balance for me in this regard.

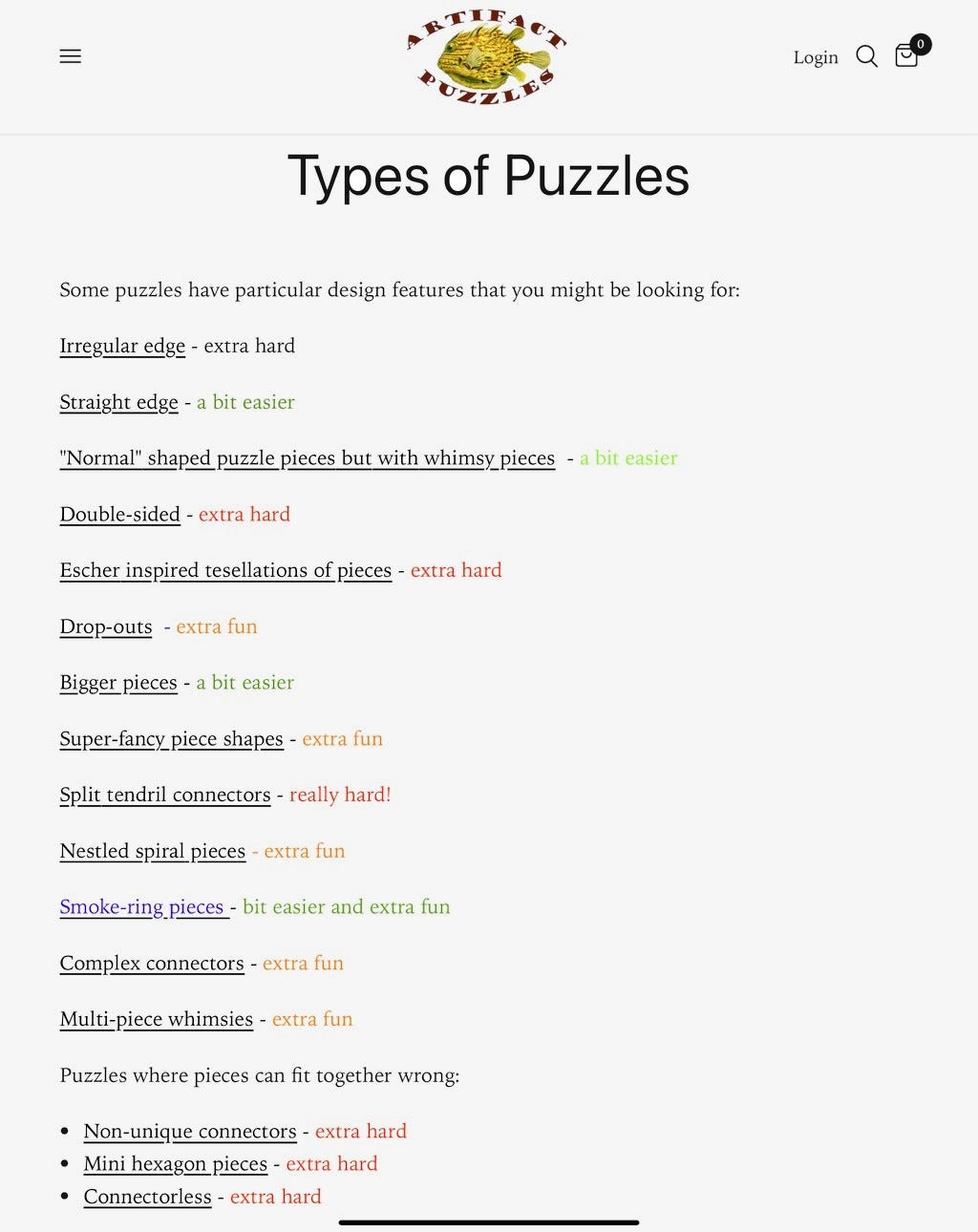

In addition to its drop-down menu for degree of difficulty, Artifact also has a dropdown menu that lets you shop for some for certain cutting design characteristics. It includes a very handy explanation of how various cutting features affect difficulty.

Some of Artifact’s cutting features, like split tendril connectors and smoke ring pieces, appear to have been invented by that company’s designers. My only dispute with this categorization list is that in my experience drop-outs make assembly extra challenging as well as extra fun.

This menu is useful but it does not address some of my personal cutting preferences. I generally prefer cutting that uses sensuous curves rather than with straight lines and geometric shapes. I also tend to prefer puzzles with only a few figural pieces rather than lots of them. I can get that information from the text descriptions and photos of the non-whimsy pieces in the catalog entry for individual puzzles, but there does not appear to be a way to filter searches for those characteristics (except that having more whimsies tends to be associated with a lower degree of difficulty). But that isn’t a criticism of Artifact. I can’t filter my searches for those factors on any other companies’ websites either.

Cutting designs

Perhaps Artifact’s biggest strength is their huge variety of cutting styles. Artifact and Ecru puzzles are designed by several different individuals each with his or her own bag of tricks. How many designers? The answer is found in another dropdown menu (since you can also search by designer.) There are 22 named individuals and they sometimes work collaboratively on specific puzzles. Add to that, the designers appear to be encouraged to experiment with new cutting styles, so they themselves do not necessarily have a personal style. The result is huge diversity and creativity.

Whimsies and irregular edges seem to get all of the attention when people talk about the joys of wood puzzles, but in my mind it is really the non-figural pieces that make this kind of puzzle so much fun. The durability of wood enables cutting that is much more interesting than the iconic four-square pieces with knob connectors found in most cardboard puzzles. In 2014 Artifact puzzles founder and CEO Maya Gupta told a reporter: “We spend a lot of time deciding how to design the pieces. Shapes and sizes are what make puzzles interesting. A puzzle needs to look good in pieces as well as when it’s put together.”

Maya’s reference to size as being a component in cutting design is because she considers more consistently sized puzzles to be more challenging to assemble and aesthetically more refined. Certainly, in the world of hand-cutting too large of a range of sizes among the pieces is often interpreted as an indicator of inexperience. But I have assembled puzzles from other makers that have considerable size inconsistency and it doesn’t make much difference for me.

For Artifact and Ecru puzzles, size consistency also seems to apply across the company’s various puzzles, with the pieces averaging about 2.5 to 3 cm²/pc (2 to 2½ pieces per inch). Aesthetically I think that is a very good size for pieces that are 5mm thick.

There are other factors in the company’s style guidance for its designers. For example, whimsies must clearly be related to themes in the puzzles image, and all pieces must be sufficiently durable to withstand potential rough handling during shipping. Pieces in family-friendly puzzles shouldn't be susceptible to breaking when subjected to the curiosity of an average 8 year old. I saw no potentially fragile pieces in any of my Artifact puzzles (but I have occasionally had puzzles arrive with broken pieces from some lower- and mid-tier makers).

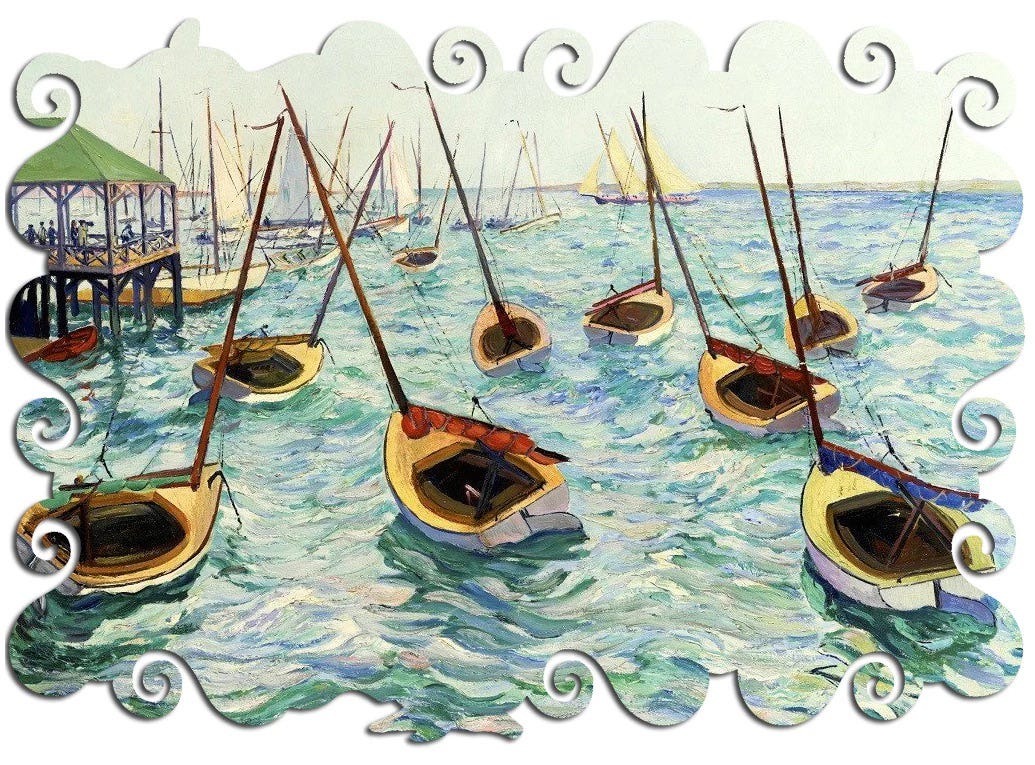

On its cover website page Artifact describes itself as making “the best artsy wooden jigsaw puzzles.” All of the top tier brands have great cutting but Artifact stands out not just for its variety of cutting styles but also for the sheer quality of their cutting designs. The abundance and beauty of their ornate irregular edges, and the simple elegance of their silhouette pieces are among the very best.

Their puzzles’ whimsies are all custom-designed for the individual puzzles – no re-use of figural designs from an internal whimsy catalog. Not only do they complement the artworks’ themes but they are often true silhouettes with accent lines often not needed to make the shape recognizable.

Artifact and Ecru puzzles use various kinds of classic connectors, such as knobs, earlets and spirals, but the designers often also develop special creative connectors related to the theme set by the puzzles’ image. My double-sided Van Gogh puzzle with farm scenes on both sides had a variety of shapes of horses’ hooves as connectors; Shiba Benten Pond had garden foliage connectors; and many of the ones for Rosso Angelo were little wings:

Another of the cutting techniques that Artifact frequently uses is giving their puzzles shaped or irregular edges, ranging from simple zig-zags to very elaborate scenes. In fact, I would estimate that well over half of their puzzles do not assemble to become simple rectangles. Irregular edges are always shown on the website but not on the image on boxes’ covers: That both adds to the challenge and to the joy of discovery during assembly.

Irregular edges, especially elaborate ones as shown above, certainly do add an additional (and sometimes whimsical) element to the appearance of the finished puzzle. But personally I have mixed feelings about them when the artwork itself is fine art and the irregular edge cuts into the image of the original painting rather than building decorative a frame around it. In such cases it can draw attention away from the image and even detract from the artist’s intended composition. In the case in a puzzle made by a different company (Mediterranean Summer, discussed near the end of this review) a decorative edge cutaway disguised something that may be an important element in understanding the painting.

My inclination is to think that the artist’s original composition should be respected: I have deferred buying some otherwise very appealing Artifact and Ecru puzzles because I thought that the edge cutting, beautiful though it was, unnecessarily altered the artist’s own composition.

I appreciate that jigsaw puzzles are an interaction between two creative processes and the result can, and perhaps should, enhance the original image. Indeed, irregular edges and shaping have been a positive asset in many of the puzzles I have assembled including these bird puzzles; and the severe cropping of Don’t Make a Noise (reported here) definitely made for a better assembly experience than the full image would have provided. But it may take a while before I become comfortable with alterations to fine art paintings.

There is one elegant and challenging cutting technique that I have not seen used by Artifact or Ecru designers, or in very many other laser-cut puzzles for that matter. Colour-line cutting (cutting that follows natural colour or texture divisions in the artwork) is a technique used by some of the very best jigsaw puzzle hand-cutters. It adds an extra dimension of challenge to puzzle assembly and would seem to be amenable to the new technology.

I asked Maya Gupta about this. She said that they do have one puzzle that is colour-line cut but confirmed that this kind of cutting “is hard to get right” using the laser technology and requires very careful alignment. She said that she and her production team have a few ideas as to how to do it expeditiously, but those thoughts compete for their R&D time with other exciting new ideas. However they might be releasing another colour-line puzzle as early as later this year.

Wood

Speaking of Artifact’s R&D, they use the same wood for both Ecru and Artifact-branded puzzles. It is Columbia Forest Products’ PureBond quarter-inch thick three-ply plywood with a poplar core, but that calls for a bit of an explanation beginning with the phrase “quarter-inch thick.” Actually, the wood is only 5 millimetres thick while a true ¼ inch would be 6.35 millimetres.

The problem is longstanding American wood industry terminology: A board that is 1½” by 3½” is commonly called a 2x4, and plywood that is 5 mm thick is called 1/4 inch. That terminology was established before construction wood was routinely planed and sanded by the manufacturers. I don’t know if ¼ inch is the thickness of this plywood before it was sanded, or if it is just standardized American rounding-up for this dimension. But that is the American wood industry jargon so Artifact is not being intentionally misleading to foreign buyers when they call their puzzles ¼” thick.

(As a Canadian I should note that although since metrification in 1975 we still call that same undersized construction board a 2x4, but in this range of thickness we use metric measurements: Only plywood that is 6mm or more thick is called quarter inch. Thus, a quarter inch thick puzzle from a Canadian maker like StumpCraft, Puzzle Lab or Palmaris really is a full ¼ inch thick, not 5mm.)

Columbia Forest Products is a company and “Purebond” is their trademarked name for its Forest Stewardship Council (FSC) certified hardwood plywood that is made using a proprietary method that has no formaldehyde in its binding agents or glue. (There is still a small amount of formaldehyde in the puzzles because it naturally occurs in all woods and is impossible to remove.)

For many years urea formaldehyde resin was the standard material used as the resin glue for making plywood, but it has a number of health risks including being classified as a known carcinogen. PureBond® plywood is made using a recently invented process. Here is its backstory as told on the CFP website (lightly edited):

As the Pacific Ocean swirled around him, a question rushed into Dr. Kaichang Li’s head: How do mussels keep their grip on rocks that are constantly pounded by waves? Dr. Li, a professor at Oregon State University’s College of Forestry, found that mussels secrete proteins known as byssal threads, which provide superior strength and extraordinary flexibility.

His curiosity led to ground-breaking research – funded by Columbia Forest Products and others – based in the principles of biomimicry, which studies nature and then imitates its designs and processes to solve human problems. Li discovered that soy proteins can be [polymerized] to perform similarly to byssal threads. And not only did they deliver phenomenal adhesion, they also offered exceptional water resistance. This breakthrough led to PureBond, proving that enhanced environmental quality and increased product performance can go hand in hand.

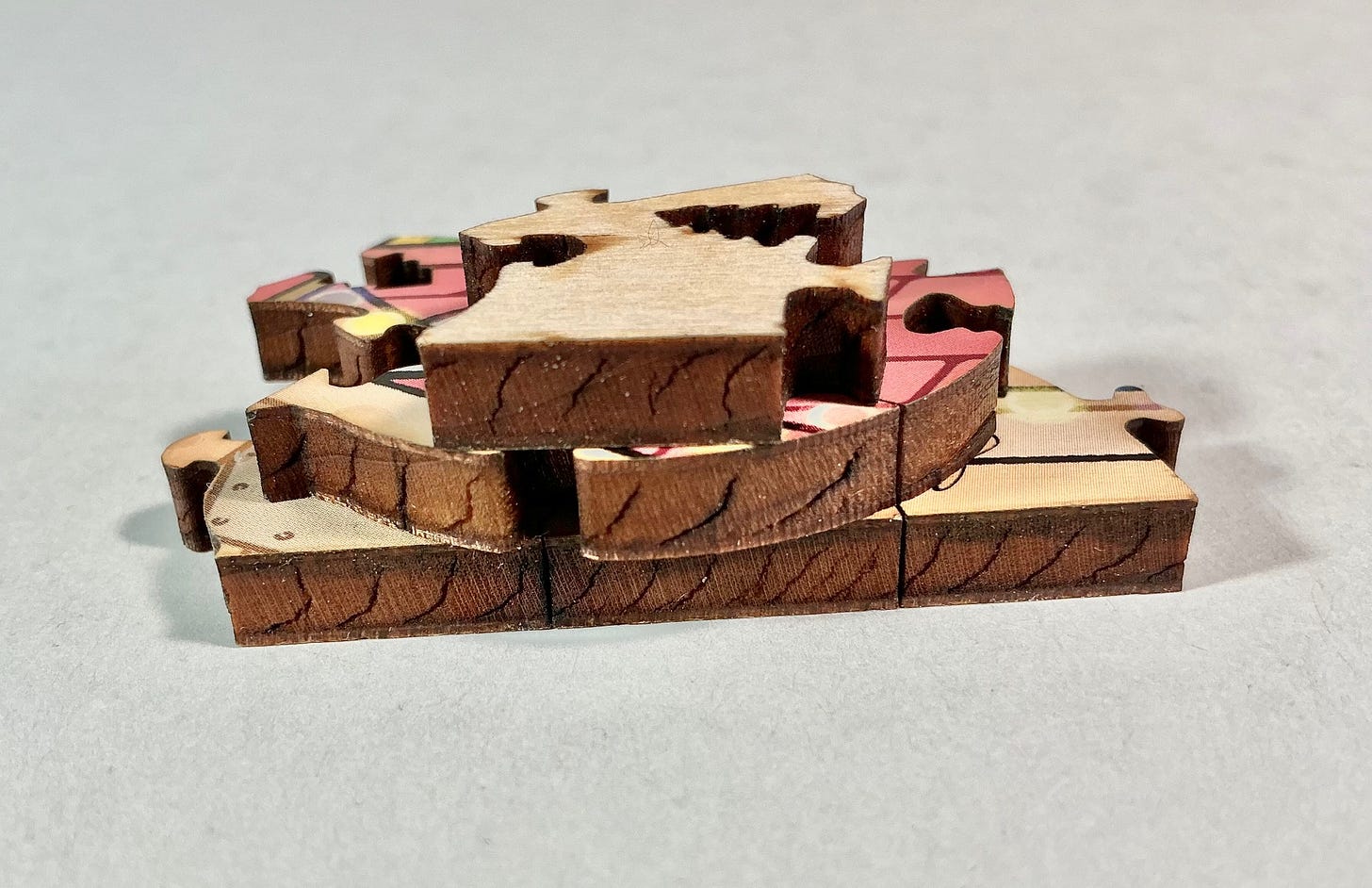

Quarter-inch plywood has traditionally been made using five criss-crossed layers of wood veneer. But if you look at the sides of the pieces of recent high quality laser-cut jigsaw puzzles you will see that the wood now is often either all medium-density fibreboard (MDF) or three-ply plywood with the outer veneers being high density hardwood encasing a single very thick inner core. The core material could be either MDF or a lightweight wood that is tough and stable (resistant to warping).

In the case of many North American made puzzles, including Artifact, hard maple is the veneer layer that encases a thick layer of poplar wood. Poplar trees are deciduous so it is technically a hardwood, but it is relatively soft and lightweight – about half the density of the maple. But it is still a tough material that resists warping, and its low density make it very suitable for laser, and without the need for as much over-burning to prevent incomplete cut-through.

From a puzzle assembly perspective, a denser interior material like MDF or a harder hardwood, would give each piece a richer tactile feel because of its greater weight. But for a variety of technical reasons the less dense but equally strong poplar is much more suitable for laser-cutting, the main one being that the lasers have to vaporize only about half as much material to make the cuts.

Poplar isn’t used as a construction wood (except mouldings and trim) and it doesn’t have an attractive colour and grain structure like classy furniture hardwoods, so we don’t hear about it much. But it does have many good features that have long made it the preferred North American wood for uses like framing in upholstered furniture, painted cabinetry, and picture frames. And now recently, as a plywood core material for North American wooden jigsaw puzzles.

Maya told me an interesting story about that:

Funny story, it took us years, years I tell you, to figure out a custom plywood that worked really well for laser-cutting puzzles. So when we moved our workshop from Fremont to Port Townsend and had to go through a different lumber yard to order our wood, we were anxious about them ordering exactly the right thing.

Maya: “Okay, please order 100 sheets of wood from Columbia Forest Products that meets these 8 bullet points, really important you get them to do all 8 of these things!”

Edensaw Woods in Port Townsend: “Yea sure, we got it.”

Maya: “No really, are you sure you’re getting the right wood? We won’t pay for it if it doesn’t meet all 8 of those constraints!”

Edensaw Woods in Port Townsend: “We’re sure, they knew just what we were talking about, they call it Puzzle Ply.”

That is, Columbia Forest Products had (wisely) taken our R&D into the perfect wood for laser-cutting puzzles, and packaged it as a new product, and now sells it to various puzzle-makers! That’s the problem with using outside suppliers, it’s real hard to keep your manufacturing secrets a secret!

But that has also been a win for us, because now Columbia Forest Products keeps a steady supply of it available!

Printing

There is not much to say here. Artifact wouldn’t qualify to be among the top tier of puzzle-makers if their printing wasn’t excellent, and that is what it is. Colour printing technology has improved by leaps and bounds in recent years, and one of the improvements has been the development of soy-based rather than petroleum-based inks. Soybean oil is naturally clear so it is a carrier that does not dull the colours of pigments, enabling sharp, true colours in the images.

Since it is not a petroleum product, such ink is considered to be environmentally friendly, but it is slower to dry than other organic inks. That slowness is due to a lack of evaporative solvents, which itself is another a factor in environmental friendliness. But it is not compatible with UV printing and therefore cannot be applied directly onto wood. Thus, like traditional puzzle-making, the image must be printed on special paper and the paper then affixed to the plywood substrate. But the quality of paper that is used these days is also much improved. I see no signs that my Artifact puzzles might be subject to subject to the kind of wear along the edges of the cuts that is common in vintage puzzles and which I have also sometimes seen in some lower-quality new ones.

Cutting execution

Artifact is quite up-front about the fact that its Artifact-branded and Ecru puzzles represent two different tiers of cost-of-production and quality with regard to cutting. Ecru’s cut-lines are both narrower and less prominent when looking at the assembled puzzle. This makes them seem more like hand-cut puzzles than the standard Artifact-branded ones.

Also, unlike Artifact-branded ones in which the printed surface is glossy, Ecru puzzles have a matte finish. The reduced reflections are certainly easier on the eyes during assembly but that is also what makes Ecru puzzles more expensive. According to Maya:

… it's easier to burn [damage] a matte print when you laser-cut it. To minimize visible scorching on matte images, you need to get everything right: the wood has to be perfectly flat, the laser focus has to be perfect and the laser mirrors perfectly clean, and your laser-cutter settings must be perfectly adjusted to the day's humidity and temperature.

Then once you've cut it, you've got to clean the very thin layer of soot left by the laser-cutting off, and the matte images are less-protected so it's easier to over-clean the image and ruin the puzzle. All that costs more.

I suppose that since my qualification standard for being among the top-tier laser-cut puzzles is that there be no technical shortcomings, perhaps Artifact-branded puzzles should be disqualified and relegated to the top end of the mid-range due to their more prominent cut-lines. But in my opinion the sheer excellence and diversity of cutting styles earns them bonus points in the overall cutting category, and frankly, while assembling them the added prominence of the cut-lines did not really draw my attention.

In fact, maybe the slightly more pronounced cut-lines of the Artifact line puzzles should be thought of as more a matter of personal preference rather than being lesser quality. Looking at a completed Ecru-branded puzzle is more like looking at an art print (if you don’t focus on looking for the lines.) An Artifact-branded puzzle instead looks exactly like what it is – a completed puzzle. The lines are not so conspicuous that they significantly detract from appreciating the image as they sometimes do in lower- and mid-range puzzles that have massive over-burn – they are just reminders that this is the beautiful puzzle that you have been enjoying assembling.

Making top quality laser-cut puzzles requires using the best industrial-strength laser cutting equipment, operated by knowledgeable professionals. And I’m sure that selecting the right machines for the job, and the specs for the custom-designed exhaust systems that must accompany them, were decisions that electrical engineer Maya could really sink her teeth into.

Over the years, as the company has grown Artifact has had cutting machines from a couple of different companies, including from the highly-regarded Trotec company in Austria. They liked those but found them not to be as good “for the ergonomics of our workflow” as the Fusion brand ones made in Colorado by Epilog. According to Maya “they make very solid & safe lasers you can run 24/7 and rely on.” They are indeed among the best you can buy (and they cost about $50,000.)

As you might guess, such professional industrial grade equipment is not just “plug & play.” As mentioned above, the machines require careful adjustments to focus and tune the cutting to the density of the material being cut and the exact thickness of that material. Much of this has to be garnered through testing and experience. According to Artifact’s long-time Head of Operations Jorge Rodriguez:

Part of what makes our puzzles stand out are the quality of the cut lines, for example the consistency of the cut and finish from top to bottom. You have to really find that sweet spot of cutting through a wood material, while at the same time not burning the puzzle image on top, and keeping a consistent cut throughout.

Wood warps due to many different factors and adjusting our cutting processes to make sure we can get high quality puzzles at the end took us some time in which we learned a few tricks. . . .

When I first started working here I would find myself chiselling the backs of our puzzles a lot to get them to separate, because the laser-cutting wasn't 100%. Fast forward to now, and we have greatly improved in how good our laser-cutting is. It was a combination of the newer lasers but also staying on top of routine maintenance. We made great puzzles 10+ years ago, but I feel that you can definitely see our growth in achieving higher quality.

Packaging, fulfillment and shipping

Separate from images, cutting design, and execution, excellence in how the puzzles are packaged and orders are filled is essential to being considered one of the top-tier puzzle-makers, and Artifact is also right up there on all those fronts.

I discussed Artifact’s packaging in some detail in my 2022 review of Woman with a Parasol and nothing has changed: They make a good first impression; classy slide-top wood boxes for the larger puzzles, and attractive and sturdy blue magnet closure boxes for the smaller ones. (Note: Artifact recently announced that they will be transitioning away from the wooden boxes for large puzzles, replacing them with telescoping-lid versions of their blue boxes.)

The Artifact website highlights the fact that their prices include free shipping. Maya told me that this is to ensure there are no nasty surprises when customers get to check-out and that even within the USA the value of that free shipping approach is pretty uneven: Hawaii and East Coast customers get the best deal out of it because they are the most expensive places for Artifact to ship to.

But international buyers are familiar with the fact that whenever an American company says “free shipping” it only applies to American customers because international shipping rates are so expensive compared to their domestic ones. When I see “free shipping” it means that I will have to pay for that American shipping as well as for the inevitable international shipping charge unless the company were to adjust for that with a credit or a price reduction that is built into the Canadian currency price.

The cost of Artifact’s international shipping is hard to find on the website without initiating an order, but in the FAQ it clarifies that there is a flat-rate shipping price for any size of international order. Currently that is $30 USD to Canada, $40 to Western Europe, and $50 to Australia/NZ/Japan/Taiwan/Malaysia/Singapore. Maya told me those rates roughly cover their average actual cost of shipping a 300 piece puzzle to those various country. If an international customer places an order for more puzzles they do get a net benefit that counteracts the cost of American shipping that is built into the puzzles’ prices.

I mentioned in the introduction to this review that I recently ordered nine more puzzles from the company. I bought that many because I had figured that out for myself. Using their online ordering system was straightforward, with an almost instant automated confirmation. Within three hours I received notification that my order was on its way, and within two days I was notified that my shipment was being processed by Canada Customs. Things slowed down after that, but it was due to errors made by UPS (which was used instead of the postal service because of a recent Canadian Post strike/lockout.) Those problems were not Artifact’s fault.

Miscellaneous and conclusions

At the very bottom of Artifact’s main webpage there is a button that enables the prices to be in US dollars or in any of several other currencies. I presume that these are kept updated by the Shopify marketing and ordering software since international exchange rates can be pretty volatile.

Some laser-cutting puzzle-makers emulate the practice of many hand-cutters of custom cutting puzzles after an order is received. The big advantage of this approach for the maker is that they do not have to maintain an inventory of pre-cut puzzles. But it does mean that there will be a time-gap between when an order is received and when it is ready for shipping.

Artifact does it just the opposite: They manufacture their puzzles in fairly large batches, I presume partly to realize what economists call “economies of scale” but also to maintain quality control. As mentioned above, laser machines work to exceedingly fine tolerances and must be finely tuned regarding many variables including factors that can change from day to day such as ambient temperature and humidity. The cutting settings that work perfectly on one day may not work well at all on another. Artifact doesn’t want to routinely over-burn to ensure a complete cut. By making their puzzles in batches they can fine-tune to current conditions so that all of the puzzles they make will be up to their high standards.

The downside of this approach is that they must keep a large inventory of various ready-made puzzles in stock, but the upside is that if a customer places an order it can be filled almost immediately, as mine was.

On a similar vein, unlike some other jigsaw puzzle companies Artifact does not make custom puzzles from customers’ photos or artwork using generic cutting designs for custom cutting. This is logical on that same basis, but also considering the importance that the company places on the interaction between the image and the cutting design including (when applicable) its distinctive figural pieces. They are willing to make custom puzzles with their own custom-made cutting designs for orders of 250 or more puzzles, and also are willing to consider proposals from museums, art galleries and artists that they design a puzzle using a particular piece of art.

The Artifact Blog frequently warns puzzlers (here is just one of them) to keep their pets away from jigsaw puzzles. Their gnawing or wandering off with pieces is a serious problem, especially with valuable wood puzzles in which the pieces are so tantalizingly chewable. But in the event of such an occurrence the Artifact FAQ says that customers can get a replacement piece for $15, or up to three of them for $22. (In the very unlikely event that a piece is missing from a new puzzle the replacement is free.)

Artifact’s online catalog includes a feature that I can’t recall seeing from any other puzzle-maker. Besides selling their own puzzles they also sell high quality ones made by their Canadian laser-cutting competitor StumpCraft, and selected pre-made hand-cut ones made by Brookie Biglands (Biglands Puzzles, formerly known as BCB) of Indiana and Georgi Vasilev (Mr. Gogo Puzzles) of Bulgaria. As with their own puzzles, these are only listed as being available if they have a puzzle in stock and ready to go, and their free shipping to American customers still applies.

Almost all of Artifact’s sales are done online from their website. They don’t have a storefront office at their workshop/factory even though it is in a tourist town, and they don’t set up booths at summer or pre-Christmas art and craft markets. The only exception seems to be participation in a local street fairs organized by the Port Townsend Arts Guild.

On the other hand, Artifact is associated with a service that is not otherwise available in the world of laser-cut puzzles in the US. Maya has spun off a separate entity called the Hoefnagel Wooden Jigsaw Puzzles Club. It is a revival of the puzzle library format that thrived for wooden puzzles in earlier times through which people rent rather than buy high quality wood puzzles. You can read more about Hoefnagel in Part 1 of this series.

The Hoefnagel club format works best for ravenous wood puzzle people, not occasional assemblers. But the social media discussion groups are filled with happy customers who are very pleased about the cost savings it gives them and who highly recommend it for people who are new to wooden puzzles and want to try out various brands to see what they are like. I have never read a post that was critical of the Hoefnagel company.

Because I like to try out various brands Club membership would be perfect for me, but unfortunately because of international postage costs only Americans can participate.

Usually I end my reviews with a summary of my conclusions, but in this case that has rather permeated the whole review. In fact, I led with the conclusion that you were able to infer when I told you at the beginning that I recently ordered nine more Artifact and Ecru puzzles. Both lines are clearly among the highest quality laser-cut wooden puzzles available.

Coming up:

Part 3 of this Artifact series - assembly walk-throughs, mini-reviews and research into the images of five small Artifact and Ecru puzzles.

You’ve put in a lot of effort, and you’ve shared a lot of details—I’d have to assume that Maya Gupta and Artifact will be really impressed with your study of her/their work. Something I got especial pleasure from was reading about the reported exchange between Maya and Edensaw Woods of Port Townsend, Washington, relating to the right kind of wood to be “sandwiched” in the centres for the ideal “layered” puzzle pieces. The list of Types of Puzzles describing particular design features a hobbyist might prize was also very cool! Of the actual puzzles pictured in your write-up today, my favourite is the relatively small one (small, that is, in terms of number of pieces) depicting “Dancing Boats Marblehead.” You get top marks, Bill, for what you’ve written and displayed today.

Thanks,

Greg